First-movers win in any market. And with the cloud, you’ll move fast.

Empower your company with our certified cloud-native experts to guide you and accelerate your cloud adoption journey.

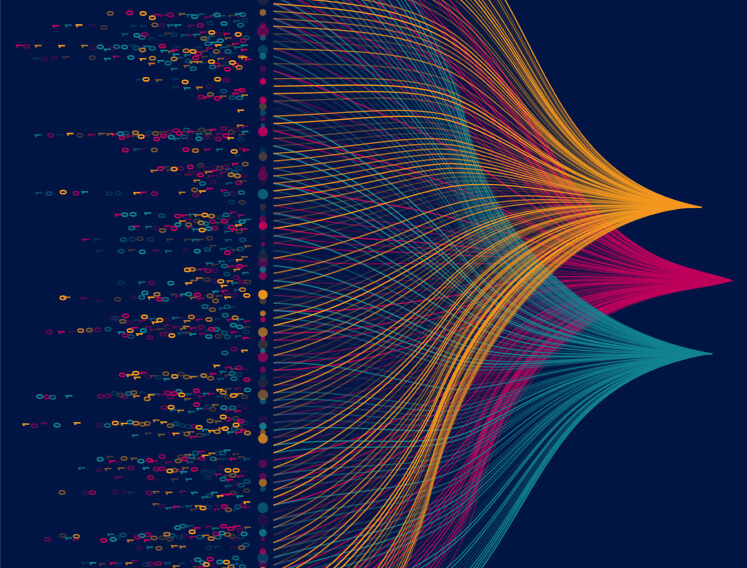

AI & ML

Cloud Migration

Trusted by SMBs and global enterprises

Both midsize businesses and Fortune 500 companies benefit from our experience. Read some of our success stories below.

Here’s what our partners say.

Accelerate your cloud adoption and keep growing

Shifting operations into the cloud is a major endeavor. Mistakes can happen: from bad architecture to security compromises, you could be looking at a costly expense. But with our certified cloud consultants, you can structure and scale your cloud solutions to maximize your business's benefits.

Revamp Your Legacy Software into Cloud-Native Apps

Transform outdated, legacy software into modern, cloud-native applications. As technology continues to evolve at an unprecedented pace, legacy applications can quickly become outdated and expensive to maintain, hindering business growth and innovation. We offer a solution to this problem, allowing businesses to revamp their legacy applications and take advantage of the latest technologies.

Get end-to-end support for your cloud journey

Creating and maintaining cloud solutions is a major engineering challenge. But you don’t have to worry about it. You keep running the business, while we handle the engineering with our team of certified cloud engineers.

Increase your developing capacity in just 2 weeks

Get a cloud engineering team on-demand, ready to tackle your new engagement. With a combination of business and technical expertise, we strive to establish long-term partnerships. All our engineers have AWS and Microsoft Azure certifications, meaning best practices are always met.

Industries we specialize in

Oil & Gas

Energy

Hydrogen

Manufacturing

Tech Stack

.png)

Here’s what our partners have to say.

If you’re wondering how to make IT work for your business

let us know to schedule a call with our sales representative.

.jpg)

.png)